Optical supermirrors have been rapidly gaining traction given their extremely high reflectivity and ultralow optical losses from scatter and absorption. They are crucial to many research and development efforts, as well as emerging industrial applications in spectroscopy, metrology, precise manufacturing, and sensing. For example, the ultra-low optical losses of optical supermirrors allow cavity ring-down spectroscopy systems to study gaseous samples with higher sensitivity and throughput than ever before.

To address this trend, a new class of Semiconductor Supermirrors has been developed that feature a single-crystal optical interference coating and provides excess optical losses (scatter and absorption) as low as 3ppm in the NIR (1064 – 1550nm) and 159ppm in the mid-IR (3 - 4μm). These Semiconductor Supermirrors outperform any other IR mirrors currently on the market due to their high reflectivity of >99.9%, low optical loss, low mechanical loss, and high thermal conductivity. Crystalline Mirror Solutions won a Prism award in the category of Materials and Coatings for this mid-IR coating technology.

|

|

Lowest mechanical loss and highest thermal conductivity of any current supermirror technology. |

|

|

Ultralow optical losses in the mid-IR surpassing that of ion-beam sputtered multilayer coated mirrors |

|

|

Microroughness of approximately 3Å |

|

|

Robust reflecting surface that can be cleaned and does not degrade |

|

|

Ideal for demanding applications including cavity ring-down spectroscopy and reference cavities for laser stabilization |

|

|

Won a Prism award in the category of Materials and Coatings |

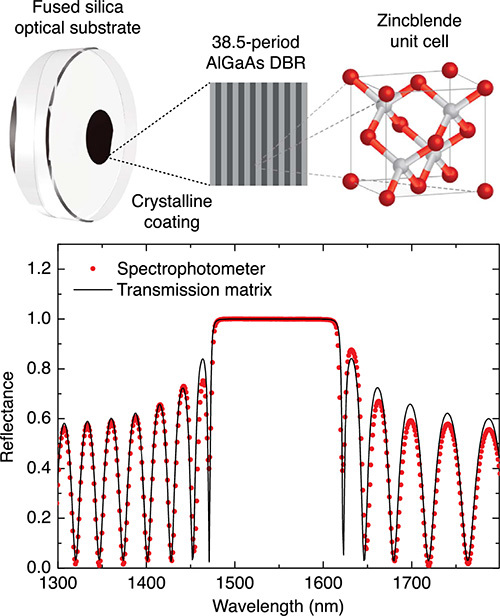

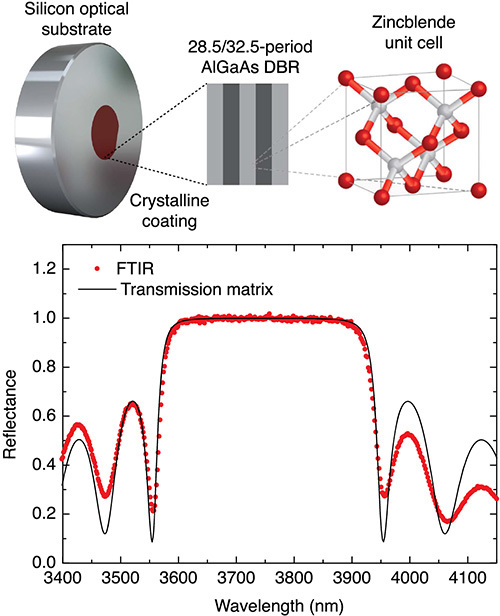

Super-polished silicon or fused silica are coated with alternating single-crystal GaAs high-index layers and Al0.92Ga0.08As low-index layers of quarter-wave optical thickness. By simply changing the thickness of the semiconductor layers, the center wavelength of the mirror is continuously tuned from 0.9 - 4.0 µm. Full details on the coating process, material structure, and optical performance are included in the research paper found in the Training Materials section below.

Graphic source "High-performance near- and mid-infrared crystalline coatings" Optica 6 June 2016: Vol. 3, No.6 (used by permission)

What are supermirrors?

What are supermirrors?

How are these different from other supermirrors?

How are these different from other supermirrors?

The crystalline coatings used to make these mirrors give them lower mechanical loss and lower thermal resistivity than ion-beam sputtered dielectric coated mirrors.

Please contact us for current in stock availability rates and to learn more about this exciting new technology.

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2023, Edmund Optics Inc., 18 Woodlands Loop #04-00, Singapore 738100

California Consumer Privacy Act (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act