Laser Beam Analysis

Laser Beam Analysis technology is used to measure the attributes of a laser beam to test its usefulness or compatibility for different laser applications. Devices such as profiler systems that evaluate data from beam images to provide information such as beam location, peak intensity position, stability, or beam density. Laser beam analysis systems offer a range of information and greater control over many laser applications by delivering detailed information about a tested laser.

Material Processing Lasers

The specific application and the material you work with will determine the necessary wavelength, power, and pulse width. We provide CO2, solid-state, and diode lasers with a broad power range, available in continuous or pulsed control.

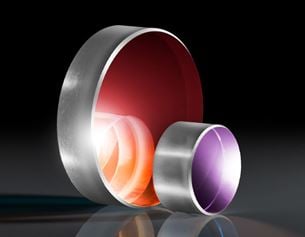

Laser Beam Expanders

Laser beam expanders provide versatility to a laser system by reducing beam divergence, improving spot size, and matching beam size to optical components. They range from designs and coatings that support CO2, Nd:YAG, UV, and Ultrashort Pulses to solutions of reflective and transmissive, variable or fixed, options like adjustable divergence, and magnifications from 1x to 20x.

Polarization Maintaining Mirrors

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

Polarization Maintaining Mirrors preserve circular polarization direction upon reflection at a 45° angle of incidence. Featuring a standard laser V-Coat of 532 or 1064nm, these mirrors achieve a high reflection of ≥99.9%. Additionally, these mirrors offer a ≥80% reflectivity at 650nm to facilitate system alignment.

Beam Steering & Scanning

Galvanometer optical scanners are well-suited for high-speed and high-power laser manufacturing applications, including laser ablation, scribing, surface cleaning, material cutting, and component marking. We offer both single and dual-axis options. Additionally, we provide a highly reflective (HR) laser coating for 1064nm on mirrors with 10, 14, and 15mm apertures. These mirrors can also be custom-coated for 355nm and 532nm laser applications. For alternate galvanometer tunings or different mirror coatings, please contact us.

Precision Waveplates for Laser Processing

These Precision Waveplates offer an exceptional damage threshold, making them ideal for material processing. They feature a premium retardance tolerance of λ/500, enabling their use in sensitive applications requiring high precision and stability. With broad bandwidth and low temperature sensitivity, these zero-order waveplates allow wavelength deviations greater than ±1%. Precision Waveplates for Laser Processing are available in 25.4 and 50.8mm diameters and are designed for commonly used material machining wavelengths of 532, 1030, and 1064nm.

F-Theta Lenses

F-Theta Lenses provide flat fields at the image plane of scanning systems and are used with galvanometers, beam expanders, and laser sources. Optimized for fiber laser sources and Nd:YAG fundamental or second harmonic, these lenses are available in design wavelengths of 355nm, 515nm, 532nm, 1030nm, and 1064nm, with common mounting threads for easy integration into galvo systems. F-Theta Lenses are effective solutions for laser scanning and processing applications, including laser marking, engraving, cutting, drilling, and 3D modeling.

Sapphire Aspheric Lenses

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

Utilizing durable sapphire substrates, these lenses decrease contamination effects on laser performance and feature better thermal conductivity, lower thermally induced focal shift, and faster induced focal shift rise time than fused silica. Designed with material processing and advanced manufacturing in mind, their aspheric surfaces provide diffraction-limited performance at 1064nm. Sapphire Aspheric lenses are available uncoated, with a standard laser v-coat, or with custom coatings available upon request.

Laser Power Meters

Laser Power Meters measure laser beam energy, supporting various testing and application needs. They use sensors to determine the intensity of the laser's energy and are designed for specific wavelengths and intensities. They are available in multiple wavelength ranges and can be customized for different laser measurement needs.

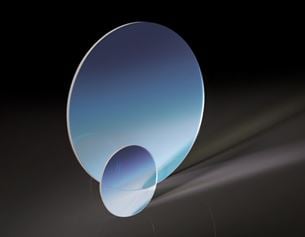

Laser Debris Shields

Laser Debris Shields, or laser cover slides or glass, are designed for use in laser machining applications and can dramatically improve the longevity of more complex optical assemblies within a system. These shields are constructed of durable fused silica or fused quartz for optimal transmission and protection from harsh manufacturing environments. Laser Debris Shields are available either uncoated, in a variety of Nd:YAG laser line Anti Reflective coatings that provide reflectivity of less than 0.25% per surface, or with a NIR I Broadband coating with reflectivity of less than 0.5% per surface.

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2024, Edmund Optics Singapore Pte. Ltd, 18 Woodlands Loop #04-00, Singapore 738100

California Consumer Privacy Acts (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act

The FUTURE Depends On Optics®