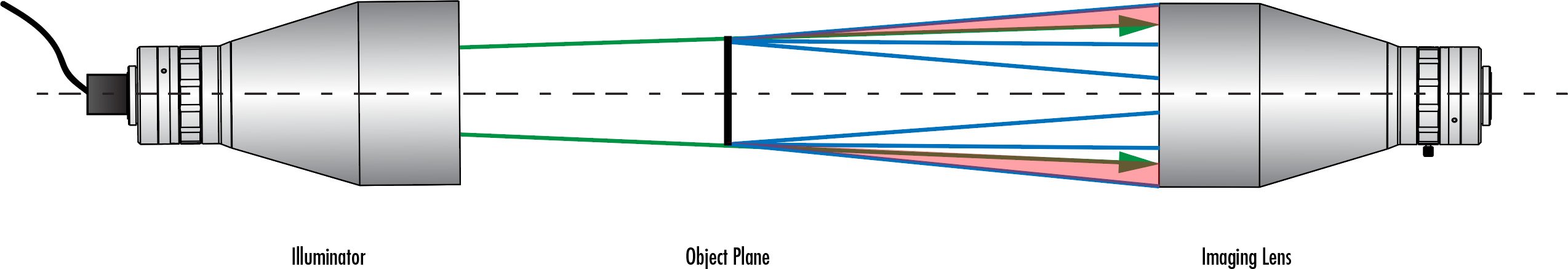

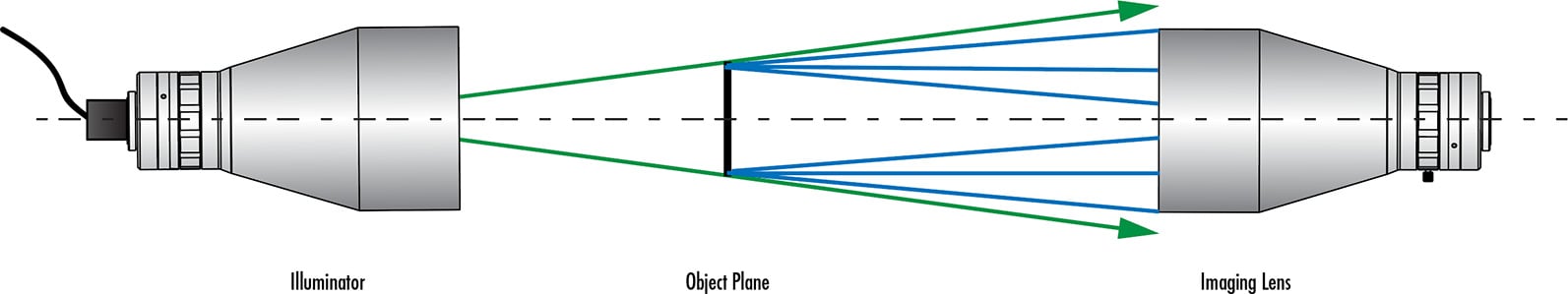

TECHSPEC® Telecentric Backlight Illuminators use the optical design principal of telecentricity to illuminate objects with truly collimated light and produce high contrast, silhouetted images. Standard backlights are diffuse to avoid hot spots, but these diffuse reflections can also reduce edge contrast. TECHSPEC® Telecentric Backlight Illuminators have collimated light rays (not diffuse) to increase edge contrast, thereby increasing measurement accuracy. Used in combination with a telecentric imaging lens, these illuminators are ideal for machine vision applications that require accurate measurements and are compatible with 8mm coaxial LEDS or ¼" (0.312") fiber optic light guides.

Note: Additional light source and light source power supply required for operation.

Technical Information

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2024, Edmund Optics Singapore Pte. Ltd, 18 Woodlands Loop #04-00, Singapore 738100

California Consumer Privacy Acts (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act

The FUTURE Depends On Optics®