In-line Telecentric Illumination for Machine Vision

Authors: Thomas Stard & Rebecca Charboneau

Introduction to In-line Telecentric Illumination

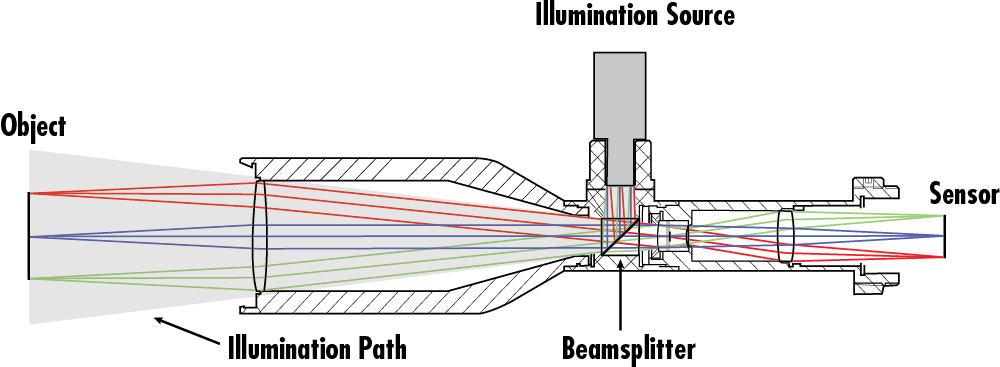

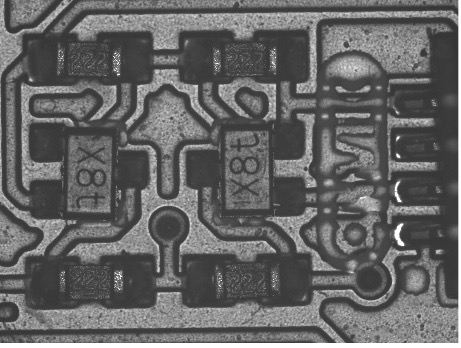

In-line illumination, when paired with a telecentric imaging lens, is a powerful technique for high-precision machine vision applications that require detection of low-contrast surface features or through-hole inspection. This coaxial lighting method directs light along the optical axis of the imaging lens using a beamsplitter, enabling even, shadow-free illumination that highlights surface defects, etched marks, or transparent features with minimal specular reflection (Figure 1). Telecentric lenses further enhance this setup by ensuring uniform magnification across the field of view and eliminating perspective errors, which is critical for accurate dimensional measurements. In this application note, example images of objects with different surfaces are observed with in-line illumination. The images below were taken with the 0.69X CobaltTL Telecentric Lens using a diffuse, white spot light to minimize hot spots.

Image Analysis and Evaluation of In-line Telecentric Illumination

| 0.69X CobaltTL Telecentric Lens |

|---|

A  |

B  |

C  |

D  |

E  |

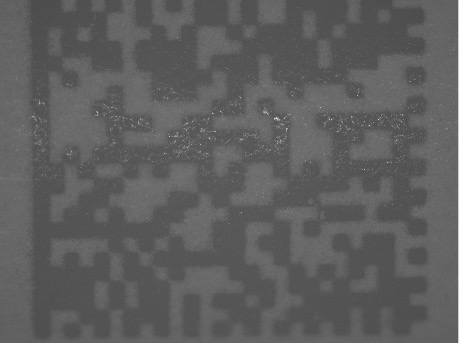

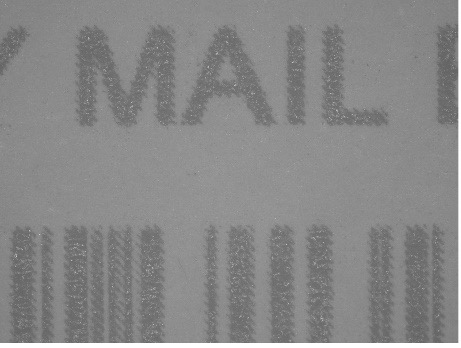

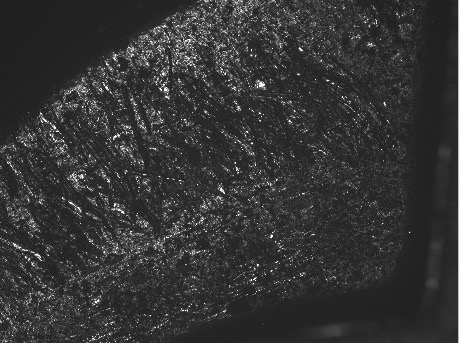

It can be observed that objects with specular surfaces benefit from in-line illumination compared to diffuse objects like the shipping label (Panel C) or plastic cap (Panel B). The features on the reflective objects like the metal part (Panel D) or electronics circuit board (Panel E) are much more distinguishable with this type of illumination. In-line illumination is particularly well-suited for applications such as inspection of semiconductor wafers, detection of micro-scratches or defects on polished surfaces, verification of laser markings on metallic components, and inspection of drilled holes in PCBs or medical devices, where conventional lighting techniques may fail to provide sufficient contrast or geometric accuracy.

Conclusion: Key Takeaways for Integrating In-line Illumination into Vision Systems

In-line telecentric illumination is a critical component in precision machine vision applications where uniform, glare-free lighting of reflective or complex surfaces is required. By directing collimated light along the same optical axis as the camera, it eliminates glare and ensures highly consistent illumination, making it ideal for inspecting transparent, specular, or cylindrical parts. When high-accuracy measurements and reliable defect detection are needed, in-line telecentric lighting delivers the uniformity and optical control necessary for robust, repeatable vision system performance..

More Resources

- Application Note: Backlight Illumination for Machine Vision

- Application Note: Brightfield Illumination with Spot and Bar Lights for Machine Vision

- Application Note: Brightfield Illumination with Dome Lights for Machine Vision

- Application Note: Brightfield Illumination with Ring Lights for Machine Vision

- Application Note: Darkfield Illumination with Ring Lights for Machine Vision

- Application Note: Common Illumination Types

- Application Note: Illumination Mounts for Machine Vision Applications

- Application Note: Relative Illumination, Roll-Off, and Vignetting

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2024, Edmund Optics Singapore Pte. Ltd, 18 Woodlands Loop #04-00, Singapore 738100

California Consumer Privacy Acts (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act

The FUTURE Depends On Optics®